BENTLY 3500/33-01-00 机械振动监测 是一种功能强大、性能稳定的设备,广泛应用于各种机械设备的状态监测和故障诊断中。它能够帮助用户及时发现设备的潜在问题,提高设备的可靠性和安全性,降低维护成本,延长设备的使用寿命。

BENTLY 3500/33-01-00 机械振动监测 详情介绍:

BENTLY 3500/33-01-00机械振动监测产品具有一系列显著的特点,这些特点使得它在机械振动监测领域中具有广泛的应用和高度的认可。

首先,BENTLY 3500/33-01-00是一款高度通用且具备故障预警功能的设备在线监测系统。它可以通过测点中的温度振动传感器实时采集机械设备(如港口起重设备的传动链,包括电动机、减速器以及轴承等)的振动信号及温度变化,从而帮助用户实时掌握机械振动信息。

其次,该产品支持多种传感器,能够实现连续、在线的监测功能,适用于各种机械保护应用。它既能进行静态(位移)测量,又能进行动态(振动)测量,功能强大且灵活。

此外,BENTLY 3500/33-01-00还具有自我检测和容错设计,可以配置成多种冗余,其范围从增添第2套完全冗余电源至完整的三重模块化冗余(TMR)配置。这种设计使得系统既可用于选定的通道,也可用于全部通道,从而充分满足最关键性任务的应用需求。

再者,该产品可以无缝连接至本特利System1状态监测与诊断分析软件平台,方便用户进行数据分析和管理。同时,它还能通过通讯网关模块与工厂控制和自动化系统进行通讯,实现数据的实时共享和远程控制。

最后,BENTLY 3500/33-01-00的设计完全符合美国石油协会API670标准对该类系统的要求,以及其他多项国际认证,如DNV和Class NK证书认证、加拿大标准协会(CSA)、工厂互助(FM)、GOST、ATEX和CE等认证。这些认证确保了产品的质量和可靠性,使其在各类应用场合中都能发挥出卓越的性能。

综上所述,BENTLY 3500/33-01-00机械振动监测产品以其高度的通用性、强大的功能、灵活的配置、高度的可靠性和广泛的认证等特点,在机械振动监测领域中脱颖而出,成为用户的首选产品。

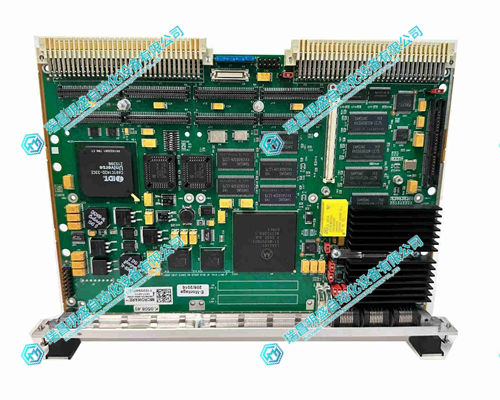

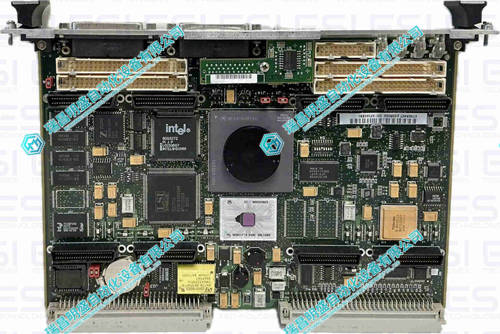

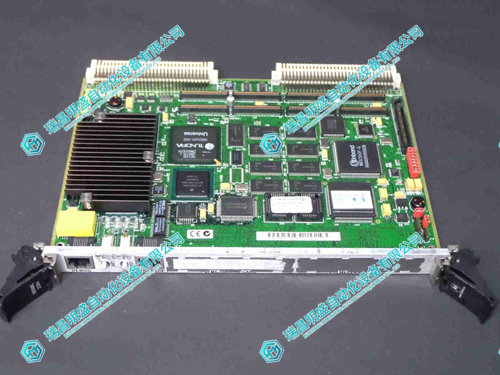

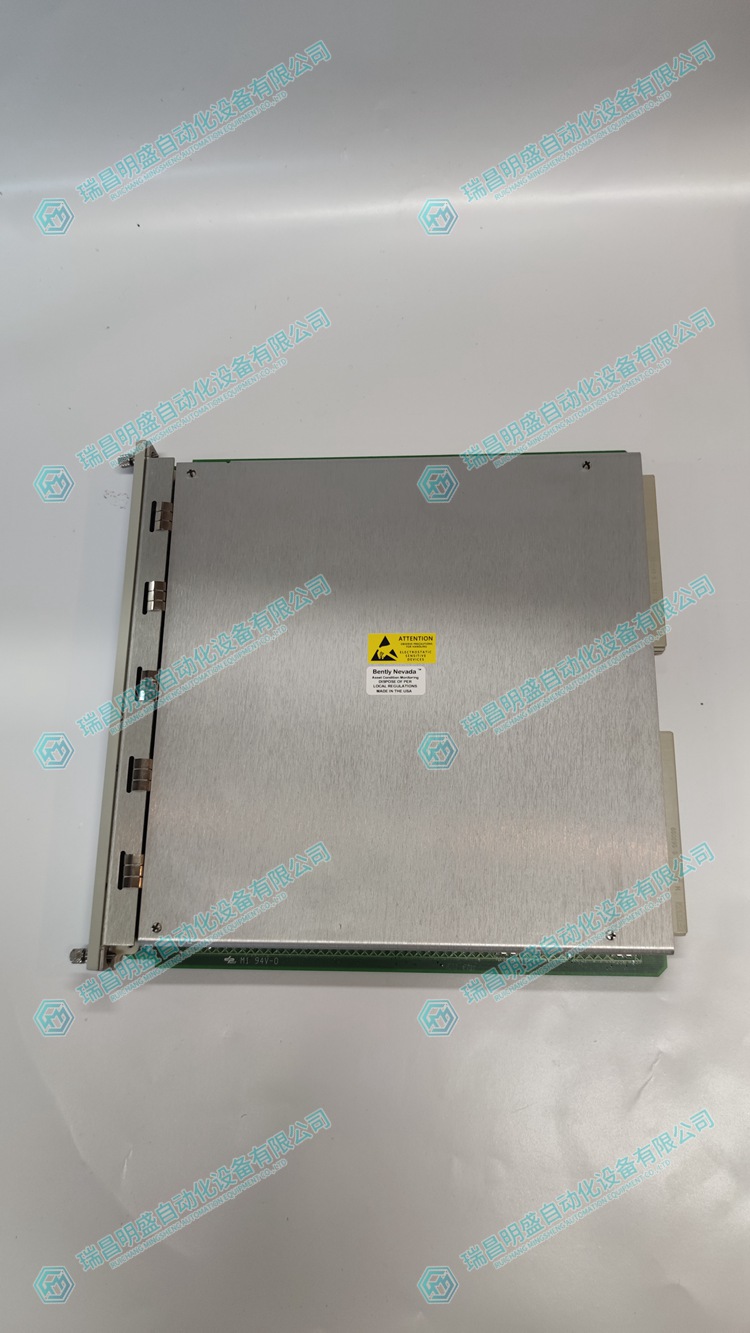

BENTLY 3500/33-01-00 机械振动监测 实物图片:

BENTLY 3500/33-01-00 机械振动监测 产品视频:

BENTLY 3500/33-01-00 Mechanical Vibration Monitoring Details Introduction:

The BENTLY 3500/33-01-00 mechanical vibration monitoring product has a series of significant characteristics, which make it widely used and highly recognized in the field of mechanical vibration monitoring.

Firstly, BENTLY 3500/33-01-00 is a highly versatile online monitoring system for equipment with fault warning functions. It can collect real-time vibration signals and temperature changes of mechanical equipment (such as the transmission chain of port lifting equipment, including electric motors, reducers, and bearings) through temperature vibration sensors in the measuring points, thereby helping users to grasp real-time mechanical vibration information.

Secondly, the product supports multiple sensors and can achieve continuous and online monitoring functions, making it suitable for various mechanical protection applications. It can perform both static (displacement) measurement and dynamic (vibration) measurement, with powerful and flexible functions.

In addition, the BENTLY 3500/33-01-00 also features self detection and fault-tolerant design, which can be configured with multiple redundancies, ranging from adding a second fully redundant power supply to a complete triple modular redundancy (TMR) configuration. This design allows the system to be used for both selected channels and all channels, fully meeting the application requirements of the most critical tasks.

Furthermore, the product can be seamlessly connected to the Bentley System1 status monitoring and diagnostic analysis software platform, facilitating user data analysis and management. At the same time, it can also communicate with factory control and automation systems through communication gateway modules, achieving real-time data sharing and remote control.

Finally, the design of BENTLY 3500/33-01-00 fully complies with the requirements of the American Petroleum Institute API670 standard for this type of system, as well as multiple international certifications such as DNV and Class NK certification, Canadian Standards Association (CSA), Factory Mutual Aid (FM), GOST, ATEX, and CE certification. These certifications ensure the quality and reliability of the product, enabling it to perform excellently in various applications.

In summary, BENTLY 3500/33-01-00 mechanical vibration monitoring products stand out in the field of mechanical vibration monitoring due to their high universality, powerful functions, flexible configuration, high reliability, and extensive certification, becoming the preferred product for users.

BENTLY 3500/33-01-00 机械振动监测 相关产品:

BENTLY 350022M 138607-01系统模块卡件

BENTLY 3500/77M 176449-07 Sensor

BENTLY 3500/20 125744-02 I/O Module

| PMB33E-20101-02 | NDLS02 | LR370A-E |

| PMB33E-20201-00 | NFTP01 | LT 370c |

| PMB33C-10216-01 | NHSS01 | K9033-015 K9033-015 ABB |

| PMB32D-00200-01 | NIAC01 | HESG 446917 R1 |