Bently 3701/55 289761-01 是Bently Nevada公司设计的一款机械状态监测设备,它主要用于监测工业设备的运行状态,特别是与振动相关的健康指标。

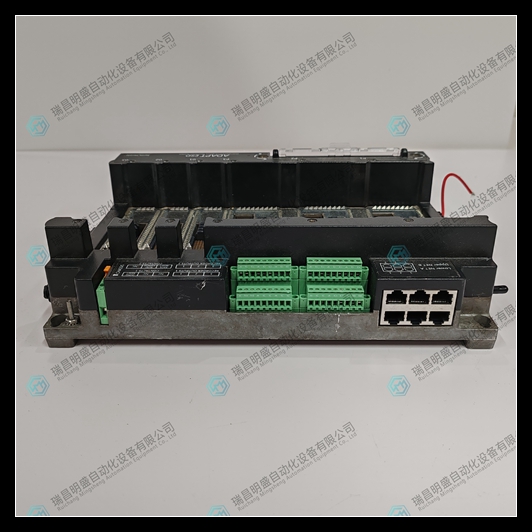

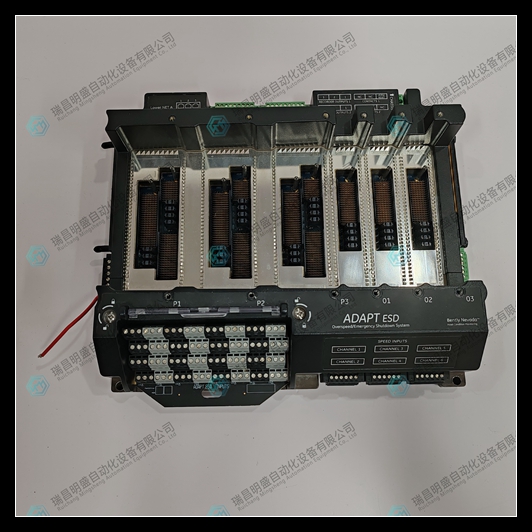

Bently 3701/55 289761-01 机械状态监测设备产品实物图片展示

Bently 3701/55 289761-01 机械状态监测设备产品视频展示

Bently 3701/55 289761-01机械状态监测设备产品特点和注意事项

Features:

High precision monitoring: This device integrates advanced sensor technology and signal processing algorithms, which can accurately measure the vibration level of rotating machinery, including key parameters such as amplitude and frequency, helping to identify potential faults in the early stage.

Intelligent analysis: It may be equipped with intelligent diagnostic functions that can automatically analyze monitoring data, identify abnormal vibration patterns, provide fault warnings, and reduce unplanned downtime.

Remote monitoring capability: By integrating into a wider range of monitoring systems, such as Bently Nevada's ADAPT platform, it can achieve remote monitoring and data analysis, making it convenient for maintenance teams to respond in real-time.

Flexible installation and compatibility: Designed to adapt to various industrial application scenarios, easy to install on different types of mechanical equipment, and usually compatible with existing monitoring systems for easy integration.

Durable and sturdy: Considering the harsh conditions of industrial environments, this equipment is usually designed with features such as dustproof, waterproof, and vibration resistance to ensure stable operation in harsh environments.

Notes:

Correct installation and calibration: Ensure installation and calibration are carried out according to the manufacturer's instructions, and the correct position and angle are crucial for monitoring accuracy.

Regular maintenance and verification: Regular maintenance and verification of equipment are carried out to ensure the sensitivity and monitoring accuracy of sensors, and to avoid performance degradation caused by long-term operation.

Environmental considerations: When used in special environments such as high temperature, humidity, and high dust, additional protective measures should be taken to ensure long-term stable operation of the equipment.

System integration: When integrating into a wider monitoring network, it is necessary to ensure the compatibility of communication protocols and correctly configure data transmission and alarm settings.

Alarm threshold setting: Reasonably set the alarm threshold to avoid frequent false alarms and ensure timely warning before actual faults occur. This needs to be adjusted based on equipment historical data and actual operating conditions.

Train operators: Ensure that operators and maintenance personnel have a full understanding of the equipment's functions, operating methods, and alarm handling processes to fully utilize its monitoring capabilities.

Bently 3701/55 289761-01 机械状态监测设备相关产品推荐

| bently 3500/15 114M5330-01 114M5335-01电源模块带小卡 | BENTLY NEVADA 3500/50 133388-02转速计监测模块 |

| BENTLY 128277-01交流驱动器 支持多种控制模式 | BENTLY NEVADA 128276-01接口模块 |