BENTLY 3500/45 176449-04位置监测器 是用于监测旋转机械轴的位置和振动的重要设备。

BENTLY 3500/45 176449-04位置监测器 详情介绍:

Bently Nevada 3500/45(型号 176449-04)位置监测器是用于监测旋转机械轴的位置和振动的重要设备。它是 Bently Nevada 3500 系列监测系统的一部分,主要用于确保机械设备的可靠运行,避免故障和提高设备的使用寿命。以下是该位置监测器的主要特性、功能和应用领域:

主要特性

高精度测量:3500/45 提供高精度的位置测量,能够准确监测旋转机械的轴位置及其变化。

振动监测:除了位置监测外,设备还支持振动测量,有助于综合评估机械设备的健康状况。

兼容性:兼容 Bently Nevada 3500 系列的其他模块,如振动监测模块和速度监测模块,能够集成到完整的监测系统中。

模块化设计:作为 3500 系列的模块化组件,可以轻松安装、配置和维护。

实时监控:提供实时数据采集和分析功能,能够即时反映设备状态,支持实时报警和通知。

高可靠性:设计上强调高可靠性和耐用性,适用于工业环境中对可靠性要求较高的应用。

诊断和报警功能:支持故障诊断和报警功能,能够及时发现潜在问题,并进行必要的维护和处理。

功能

位置测量:精确测量机械轴的位置,监控轴的运行状态,确保机械设备的正常运行。

振动分析:与振动监测功能集成,分析机械设备的振动数据,评估设备健康状况和性能。

数据记录:记录历史数据,支持趋势分析和故障预测,帮助进行设备维护和故障排查。

报警系统:根据设置的阈值,提供实时报警,提醒操作员注意设备的异常状态。

系统集成:可以与 Bently Nevada 的其他监测模块和系统进行集成,形成全面的设备健康监测解决方案。

应用领域

发电厂:在发电厂中,监测燃气轮机、蒸汽轮机和发电机的轴位置和振动,确保设备的稳定运行。

石油和天然气:在石油和天然气行业,用于监测泵、压缩机和其他旋转设备,防止故障发生。

化工厂:用于化工厂中关键设备的状态监测,如反应器、泵和混合机。

制造业:在制造业中,监测生产设备的运行状态,确保生产过程的稳定性和产品质量。

矿业:在矿业应用中,监测矿山设备,如输送机、破碎机和磨矿机的运行情况。

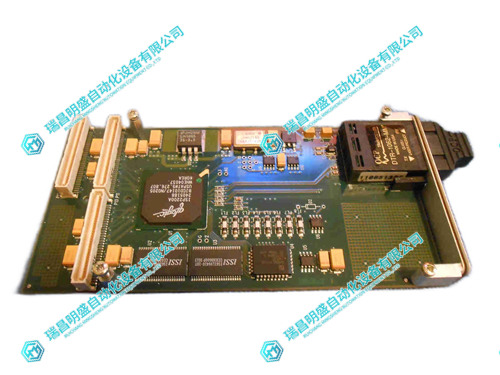

BENTLY 3500/45 176449-04位置监测器 实物图片:

english introduction:

The Bently Nevada 3500/45 (model 176449-04) position monitor is an important device used to monitor the position and vibration of rotating machinery shafts. It is part of the Bently Nevada 3500 series monitoring system, mainly used to ensure the reliable operation of mechanical equipment, avoid failures, and improve the service life of equipment. The following are the main features, functions, and application areas of the position monitor:

Main characteristics

High precision measurement: The 3500/45 provides high-precision position measurement, which can accurately monitor the axis position and its changes of rotating machinery.

Vibration monitoring: In addition to position monitoring, the equipment also supports vibration measurement, which helps to comprehensively evaluate the health status of mechanical equipment.

Compatibility: Compatible with other modules of the Bently Nevada 3500 series, such as vibration monitoring modules and speed monitoring modules, and can be integrated into a complete monitoring system.

Modular design: As a modular component of the 3500 series, it can be easily installed, configured, and maintained.

Real time monitoring: Provides real-time data collection and analysis functions, can reflect device status in real time, and supports real-time alarms and notifications.

High reliability: The design emphasizes high reliability and durability, suitable for applications in industrial environments that require high reliability.

Diagnostic and alarm functions: Supports fault diagnosis and alarm functions, enabling timely detection of potential problems and necessary maintenance and handling.

function

Position measurement: Accurately measure the position of the mechanical shaft, monitor the operating status of the shaft, and ensure the normal operation of the mechanical equipment.

Vibration analysis: Integrated with vibration monitoring function, analyze vibration data of mechanical equipment, evaluate equipment health status and performance.

Data recording: Record historical data, support trend analysis and fault prediction, assist in equipment maintenance and troubleshooting.

Alarm system: Based on the set threshold, provide real-time alarms to remind operators to pay attention to abnormal equipment status.

System integration: It can be integrated with other monitoring modules and systems from Bently Nevada to form a comprehensive equipment health monitoring solution.

application area

Power plant: In power plants, monitor the shaft position and vibration of gas turbines, steam turbines, and generators to ensure stable operation of the equipment.

Oil and gas: In the oil and gas industry, it is used to monitor pumps, compressors, and other rotating equipment to prevent malfunctions.

Chemical plant: used for status monitoring of key equipment in chemical plants, such as reactors, pumps, and mixers.

Manufacturing industry: In manufacturing, monitoring the operation status of production equipment to ensure the stability of the production process and product quality.

Mining: In mining applications, monitoring the operation of mining equipment such as conveyors, crushers, and grinders.

BENTLY 3500/45 176449-04位置监测器 相关产品:

DAPC100 Stator pressure control panel

| PMB31B-00200-00 | 70 AS 32a-E | N33HCLG-LNK-NS-01 |

| PMB31B-00201-01 | 70 AS 40b-E | N31HRHJ-LNK-NS-00 |

| PMB31B-00114-01 | 70 AS 41b-E | N32HREM-LNK-NS-00 |

| PMB33E-10214-03 | 70 AS 45b-E | N32HRFM-LNK-NS-00 |

| PMB33F-10116-01 | 70 AS 46b-E | N31HRFJ-LNK-NS-00 |

| PMB33C-10116-01 | 70 AS 47b-E | N31HRFG-LSS-M2-02 |

| PMB31B-10101-03 | 70 AS 67a-E | N32HLHJ-LNK-NS-00 |

| PMB31B-20116-00 | 70 BA 01b | N31HRHK-LEK-SS-02 |

| PMB33E-10214-01 | 70 BK 02a-E | N32HCLG-LNK-NS-01 |