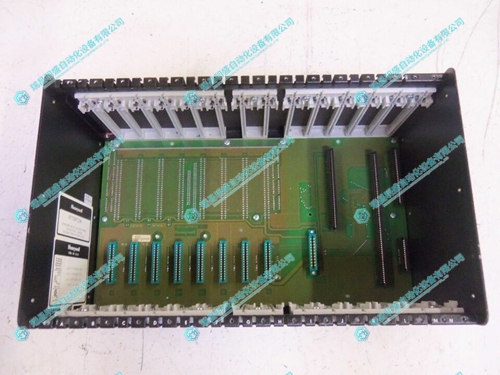

Honeywell 620-0090输入/输出机架 是一种输入/输出 (I/O) 机架,设计用于工业自动化系统中的信号处理和数据交换。

Honeywell 620-0090输入/输出机架 详情介绍:

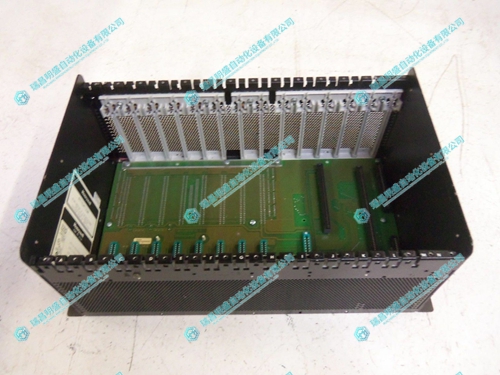

HONEYWELL 620-0090 是一种输入/输出 (I/O) 机架,设计用于工业自动化系统中的信号处理和数据交换。该机架通常与HONEYWELL的TDC 3000或其他控制系统配套使用,负责容纳和管理多个I/O模块,以实现对现场设备的控制和监控。

主要功能

- 模块化设计: 620-0090 I/O机架能够容纳多种类型的I/O模块,如模拟输入/输出、数字输入/输出和特殊功能模块。这种模块化设计允许系统根据具体需求进行灵活配置和扩展。

- 信号处理与转换: 机架中的I/O模块能够处理来自现场设备的信号,如传感器和执行器的输入信号,并将其转换为控制系统可理解的格式。此外,它还将控制系统的输出信号传输给现场设备,执行相应的操作。

- 可靠的数据传输: 机架内置的背板或通信总线确保各模块之间及与中央控制器的高效数据传输,维持系统的实时响应能力。

- 电源分配与管理: 机架提供统一的电源管理功能,确保所有安装的I/O模块都能获得稳定的电源供应,并具备过载保护等功能。

应用领域

HONEYWELL 620-0090 输入/输出机架广泛应用于多个工业领域的自动化控制系统中,以下是一些主要的应用领域:

石油和天然气

- 应用场景: 用于油气开采、运输和炼油过程中的自动化控制系统,通过I/O模块处理各种现场信号,如压力、温度和流量信号。

- 作用: 实现对油气设备的实时监控和控制,确保生产过程的安全和高效。

化工行业

- 应用场景: 在化工厂的过程控制系统中,用于管理化学反应过程中的输入/输出信号,如反应器的温度、压力和液位控制。

- 作用: 提供精准的信号处理和控制,支持复杂化学工艺的自动化操作。

电力行业

- 应用场景: 用于电力生产和配电系统的自动化控制,通过I/O模块监控和控制发电设备、变电站的运行状态。

- 作用: 确保电力系统的稳定性和安全性,支持远程监控和控制。

制造业

- 应用场景: 在自动化生产线中,用于连接和管理各种传感器和执行器,处理生产过程中的实时数据。

- 作用: 提高生产线的自动化水平和生产效率,支持复杂生产工艺的精确控制。

水处理

- 应用场景: 在污水处理厂和供水系统的自动化控制中,用于采集水质参数和控制水处理设备的运行。

- 作用: 实现水处理过程的自动化管理,确保出水水质的稳定性和合规性。

制药行业

- 应用场景: 用于制药生产过程的自动化控制,管理与监控设备的操作参数,确保生产过程符合行业标准。

- 作用: 提供高度可靠的信号处理能力,支持制药过程的严格质量控制。

食品和饮料行业

- 应用场景: 在食品和饮料加工厂的自动化系统中,用于连接和控制生产设备,监控生产过程中的关键参数。

- 作用: 提供稳定可靠的I/O处理能力,确保生产的安全性和产品质量的一致性。

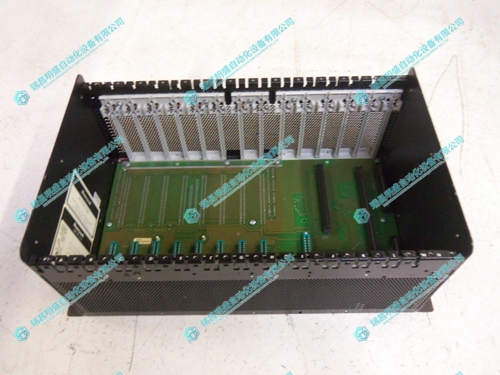

Honeywell 620-0090输入/输出机架 实物图片:

english introduction:

HONEYWELL 620-0090 is an input/output (I/O) rack designed for signal processing and data exchange in industrial automation systems. This rack is typically used in conjunction with HONEYWELL's TDC 3000 or other control systems, responsible for accommodating and managing multiple I/O modules to achieve control and monitoring of field devices.

major function

Modular design: The 620-0090 I/O rack can accommodate various types of I/O modules, such as analog input/output, digital input/output, and special function modules. This modular design allows the system to be flexibly configured and expanded according to specific needs.

Signal processing and conversion: The I/O modules in the rack are capable of processing signals from field devices, such as input signals from sensors and actuators, and converting them into a format that the control system can understand. In addition, it also transmits the output signals of the control system to the on-site devices to perform corresponding operations.

Reliable data transmission: The built-in backplane or communication bus in the rack ensures efficient data transmission between modules and with the central controller, maintaining the system's real-time response capability.

Power allocation and management: The rack provides unified power management functions, ensuring that all installed I/O modules can receive stable power supply and have overload protection and other functions.

application area

HONEYWELL 620-0090 input/output rack is widely used in automation control systems in multiple industrial fields. The following are some of the main application areas:

Oil and gas

Application scenario: Used for automated control systems in oil and gas extraction, transportation, and refining processes, processing various on-site signals such as pressure, temperature, and flow signals through I/O modules.

Function: To achieve real-time monitoring and control of oil and gas equipment, ensuring the safety and efficiency of the production process.

Chemical industry

Application scenario: In the process control system of chemical plants, it is used to manage input/output signals during chemical reaction processes, such as temperature, pressure, and liquid level control of reactors.

Function: Provide precise signal processing and control, support automated operation of complex chemical processes.

Power industry

Application scenario: Used for automation control of power production and distribution systems, monitoring and controlling the operation status of power generation equipment and substations through I/O modules.

Function: Ensure the stability and safety of the power system, support remote monitoring and control.

manufacturing

Application scenario: In automated production lines, it is used to connect and manage various sensors and actuators, and process real-time data during the production process.

Function: Improve the automation level and production efficiency of the production line, and support precise control of complex production processes.

water treatment

Application scenario: In the automation control of sewage treatment plants and water supply systems, it is used to collect water quality parameters and control the operation of water treatment equipment.

Function: To achieve automated management of water treatment processes, ensuring the stability and compliance of effluent quality.

Pharmaceutical industry

Application scenario: Used for automated control of pharmaceutical production processes, managing and monitoring equipment operating parameters to ensure that the production process meets industry standards.

Function: Provide highly reliable signal processing capabilities to support strict quality control in the pharmaceutical process.

Food and beverage industry

Application scenario: In the automation system of food and beverage processing plants, it is used to connect and control production equipment, monitor key parameters in the production process.

Function: Provide stable and reliable I/O processing capabilities to ensure production safety and product quality consistency.

Honeywell 620-0090输入/输出机架 相关产品:

JETTER DIMA3-ES-16 Distributed Control System

Jetter JM-204-480-JC310-S1 servo drive

jetter JM-204-480-JC310-S1伺服驱动器

| 45VM60-020-4 | SS2000-PCI | NMFC03 |

| 33VM62-000-76 | SP24-09A4-02 | NMFC04 |

| 55NM82-000-2 | SS2000M-D4 | NMFC05 |

| 33VM52-008-4 | PRD-P303250D-35 | NRI002 |

| 55NM82-100-2 | SRB-MS-ILK5 | NSPM01 |

| 2VM62-000-2 | P315MH422 | NSSM01 |

| 55NM81-020-5-CTRL | 51800-60 | NTAI02 |