产品标题:COMPRESSOR CONTROLS CORP MCP-1004电路控制板

型号:CORP MCP-1004

品牌:COMPRESSOR CONTROLS

质保:七天验收期,质保期一年

交货期: 1-3个工作日

快递:顺丰、德邦等

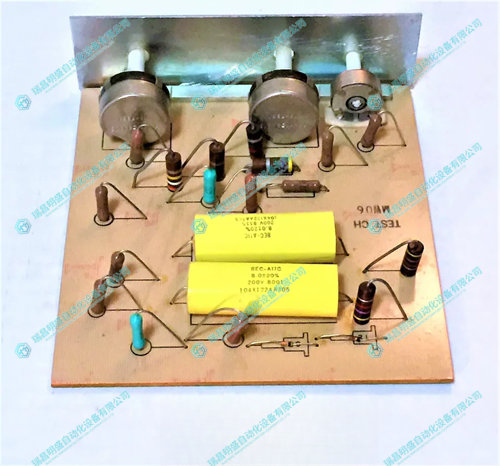

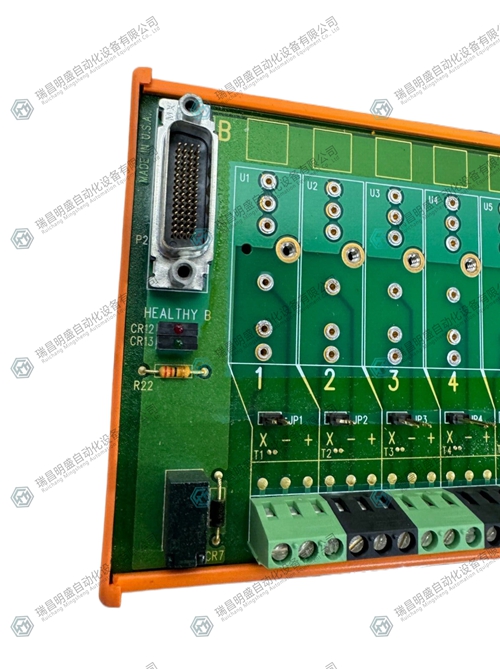

产品展示

详情

专业培训:操作和维护人员应接受相应培训,了解控制板的操作界面和故障处理流程,以确保安全高效地使用。

Efficient processor: Equipped with a 1GHz high-performance CPU, designed specifically for extreme operating conditions, it can quickly handle complex control tasks and algorithms.

Precision control: Provides precise pressure, temperature, and flow control, ensuring that the compressor operates at its optimal state through real-time monitoring and automatic adjustment.

Fault diagnosis and protection: Integrated with fault detection and diagnosis functions, it can quickly respond in abnormal situations, execute protective measures, and reduce the risk of equipment damage.

Communication capability: Usually equipped with multiple communication interfaces (such as Ethernet, Modbus, etc.), it is easy to integrate with the upper computer or automation system to achieve remote monitoring and management.

Adaptive configuration: supports software programming and parameter adjustment, and users can customize settings according to specific application requirements.

Energy efficiency management: Optimizing the operating cycle and load distribution of compressors can help save energy, reduce emissions, and lower operating costs.

Correct installation and wiring: Ensure to follow the manufacturer's manual for installation and wiring. Incorrect installation can cause damage to the control board or system malfunction.

Regular maintenance and inspection: Regularly clean the control board and surrounding environment, check for loose connections, maintain good heat dissipation conditions to prevent overheating.

Software updates and compatibility: Pay attention to the updates of the control board software, upgrade in a timely manner to obtain new features or fix known issues, and confirm that the software updates are compatible with the existing system.

Voltage and current stability: Ensure stable power supply voltage and current, unstable power supply may cause abnormal operation or damage to the control board.

Environmental conditions: Pay attention to the working environment temperature and humidity of the control board to avoid extreme environments affecting its performance and lifespan.

Professional training: Operators and maintenance personnel should receive corresponding training to understand the operation interface and fault handling process of the control board, in order to ensure safe and efficient use.

我司拥有海量库存,欢迎来电咨询报价!