AMAT 0100-09196计数器模块 是工业自动化系统中的关键组件,用于处理和控制系统中的数据和信号

AMAT 0100-09196计数器模块 详情介绍:

AMAT 0100-09196 计数器模块在半导体制造领域中具有广泛的应用,其主要应用领域包括以下几个方面:

1. 晶圆制造工艺

- 晶圆处理步骤监控:在半导体制造过程中,晶圆会经历多道工艺步骤。计数器模块可以跟踪和记录每一片晶圆在处理过程中的步骤数量,以确保每个工艺步骤的执行和控制。

2. 设备维护与监控

- 设备运行时间记录:用于记录设备的运行时间,帮助预测和规划设备的维护周期,防止设备过度使用导致的故障。

- 操作次数统计:监控关键设备组件(如阀门、开关等)的操作次数,以预测和安排必要的更换或维护,从而延长设备的使用寿命。

3. 生产过程优化

- 产量监控与统计:计数器模块可以用于统计和分析生产线上的产量数据,帮助优化生产流程,提高生产效率。

- 工艺控制与反馈:通过实时监控工艺步骤的次数,帮助工程师及时调整工艺参数,优化生产质量。

4. 故障诊断

- 异常检测与报警:在生产过程中,计数器模块可以用于监测异常的操作次数或时间,及时发出警报,防止潜在故障扩大。

5. 质量控制

- 过程一致性监控:通过记录每个制造步骤的执行次数,确保工艺的一致性和重复性,从而提高最终产品的质量。

6. 数据分析与追溯

- 历史数据记录与分析:通过对生产过程中操作次数和时间的记录,可以为后续的故障追溯和过程改进提供数据支持。

AMAT 0100-09196 计数器模块在半导体制造过程中起到了至关重要的作用,确保了生产过程的精确控制和设备的高效运行。这些应用领域直接影响到半导体产品的质量和生产效率。

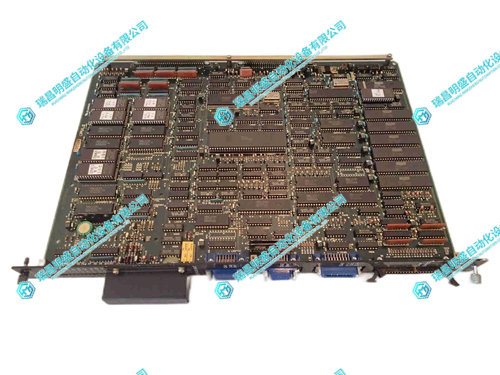

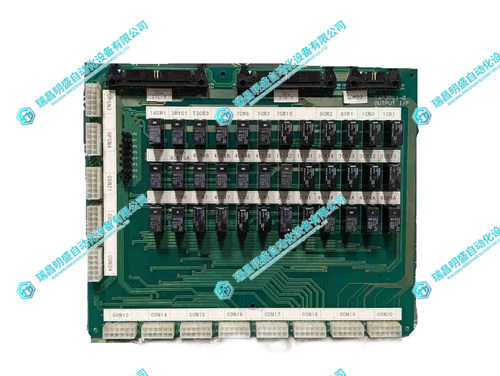

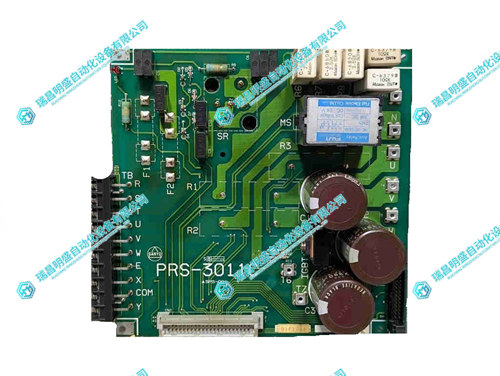

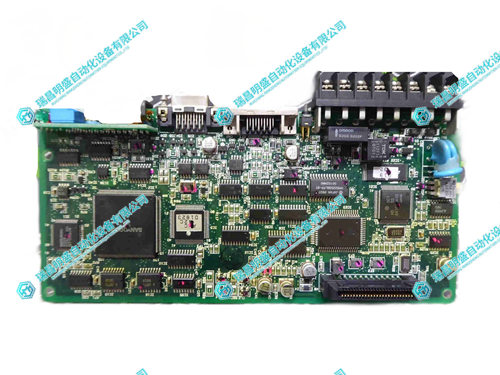

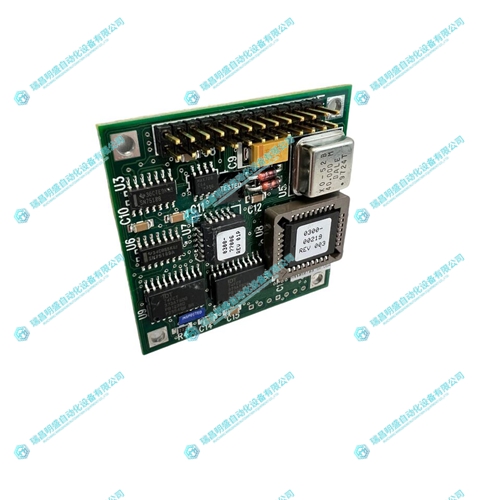

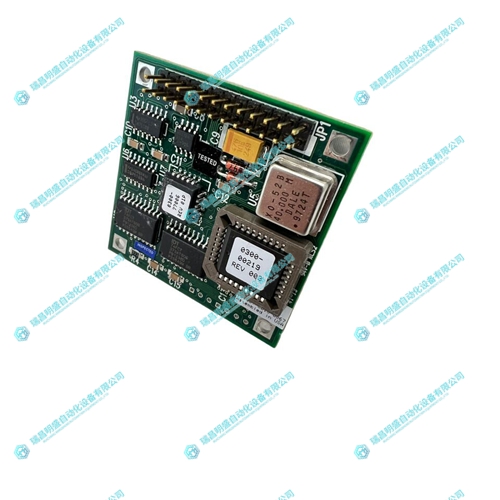

AMAT 0100-09196计数器模块 实物图片:

english introduction:

The AMAT 0100-09196 counter module has a wide range of applications in the semiconductor manufacturing field, including the following main application areas:

1. Wafer manufacturing process

Wafer processing step monitoring: In the semiconductor manufacturing process, wafers undergo multiple process steps. The counter module can track and record the number of steps in the processing of each wafer to ensure the execution and control of each process step.

2. Equipment maintenance and monitoring

Equipment running time recording: used to record the running time of equipment, help predict and plan the maintenance cycle of equipment, and prevent equipment failures caused by excessive use.

Operation frequency statistics: Monitor the operation frequency of key equipment components (such as valves, switches, etc.) to predict and arrange necessary replacement or maintenance, thereby extending the service life of the equipment.

3. Production process optimization

Production monitoring and statistics: The counter module can be used to collect and analyze production data on the production line, helping to optimize the production process and improve production efficiency.

Process control and feedback: By monitoring the number of process steps in real-time, engineers can adjust process parameters in a timely manner to optimize production quality.

4. Fault diagnosis

Abnormal detection and alarm: In the production process, the counter module can be used to monitor the number or time of abnormal operations, issue timely alarms, and prevent potential faults from expanding.

5. Quality control

Process consistency monitoring: By recording the number of times each manufacturing step is executed, the consistency and repeatability of the process are ensured, thereby improving the quality of the final product.

6. Data analysis and traceability

Historical data recording and analysis: By recording the number and time of operations in the production process, data support can be provided for subsequent fault tracing and process improvement.

The AMAT 0100-09196 counter module plays a crucial role in the semiconductor manufacturing process, ensuring precise control of the production process and efficient operation of equipment. These application areas directly affect the quality and production efficiency of semiconductor products.

AMAT 0100-09196计数器模块 相关产品:

216AB61 HESG324013R101 Digital control module

216EA61B HESG448230R1/G digital input module

UNIROL1010 3BHE035301R0001 Excitation controller

| PMB33F-00214-03 | 70 PR 02a-E | PWM3624-5579-7-1 |

| PMB33E-20200-02 | 70 PR 03c-E | PWM3652-5458-4 |

| PMB32D-00100-01 | 70 SK 30b-E | PWM3656-5102-84-3 |

| PMB33F-00101-03 | 70 SK 31b-E | PWM3636-5501-7 |

| PMB33E-20216-00 | 70 SK 32a-E | PWM3616-5329-7-2 |

| PMB33C-10100-00 | 70 SK 33b-E | PWM3632-5313-7-3 |

| PMB33E-20114-02 | 70 SK 34b-E | PWM3624-5437-7-1 |

| PMB33C-20200-03 | 70 SK 36b-E | R43HEAA-R2-NS-VS-00 |