Schneider TM251MESE可编程控制器 提供的一款可编程控制器(PLC),属于 Modicon M251 系列。

Schneider TM251MESE可编程控制器 详情介绍:

Schneider TM251MESE 是 Schneider Electric 提供的一款可编程控制器(PLC),属于 Modicon M251 系列。该控制器广泛应用于工业自动化和控制系统中,用于实现设备和过程的智能控制、监控和优化。

主要特点:

处理能力:

- 处理器:TM251MESE 配备高性能处理器,能够处理复杂的控制任务和实时数据处理。

- 内存:具有足够的内存以支持大规模的程序和数据存储需求。

输入/输出模块:

- 数字和模拟 I/O:支持多种输入/输出模块配置,包括数字量和模拟量输入/输出,能够与各种传感器、执行器和其他设备兼容。

- 模块化设计:支持模块化扩展,能够根据应用需求添加或更换 I/O 模块。

通信接口:

- 内置接口:配备多种通信接口,如 Ethernet/IP、Modbus TCP、RS-232/RS-485 等,支持与其他控制器和设备的集成。

- 扩展接口:支持扩展模块,以增加更多的通信选项和网络连接能力。

编程和配置:

- 编程软件:使用 Schneider Electric 的 EcoStruxure Control Expert 或 SoMachine 编程软件进行编程和配置,支持多种编程语言,如梯形图(Ladder Logic)、结构化文本(Structured Text)等。

- 图形化编程:提供图形化编程界面,简化控制逻辑的设计和调试过程。

功能和应用:

- 控制和监控:可用于各种工业控制应用,如生产线自动化、过程控制、设备监控等。

- 数据采集和处理:支持数据采集、实时处理和数据存储,适用于实时监控和数据分析。

扩展性:

- 模块化扩展:支持通过扩展模块增加更多的 I/O 点和功能,灵活满足不同的应用需求。

- 兼容性:与 Schneider Electric 其他自动化设备兼容,便于系统集成和升级。

技术规格(概述):

- 处理器:高性能处理器,支持快速响应和处理。

- 内存:适量内存,用于存储程序和数据。

- 输入/输出模块:支持数字量和模拟量 I/O 模块的配置和扩展。

- 通信接口:包括 Ethernet/IP、Modbus TCP、RS-232/RS-485 等。

- 编程语言:支持梯形图(Ladder Logic)、结构化文本(Structured Text)等。

- 扩展模块:支持模块化扩展,增加 I/O 点和功能。

应用领域:

- 制造业:用于生产线控制、设备监控、过程自动化等。

- 石油和天然气:控制油气开采和加工设备,监控运行状态。

- 化工行业:自动化控制化工生产过程,确保工艺稳定。

- 水处理:用于水处理设施中的设备控制和过程监控。

系统优势:

- 高性能:强大的处理能力和内存支持复杂控制任务。

- 灵活性:模块化设计和多种编程选项提供了高度的灵活性和扩展能力。

- 兼容性:与 Schneider Electric 的其他设备兼容,简化系统集成。

- 易于编程:图形化编程界面和丰富的编程语言支持,提高编程效率。

Schneider TM251MESE 可编程控制器是一款功能强大的工业控制设备,适用于各种自动化应用,提供了灵活的控制和监控解决方案。

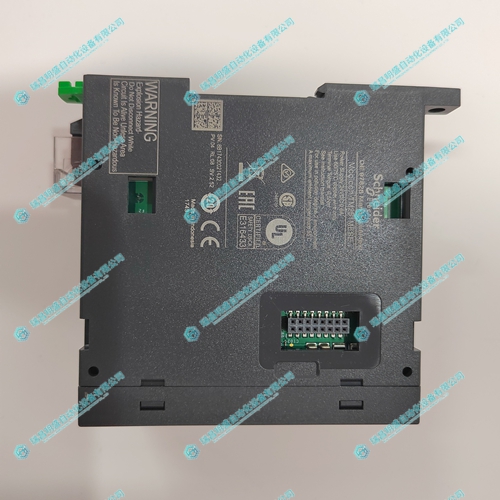

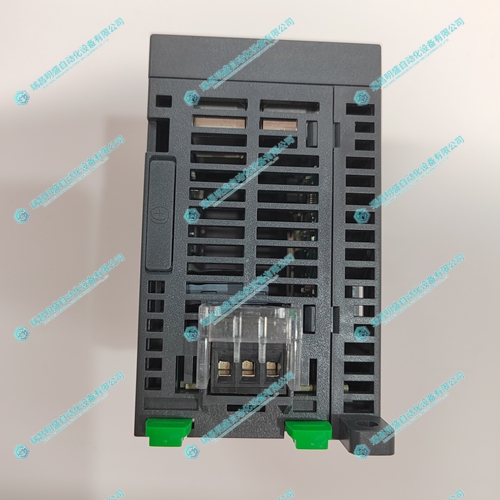

Schneider TM251MESE可编程控制器 实物图片:

english introduction:

Schneider TM251MESE is a programmable logic controller (PLC) provided by Schneider Electric, belonging to the Modicon M251 series. This controller is widely used in industrial automation and control systems to achieve intelligent control, monitoring, and optimization of equipment and processes.

Main features:

Processing ability:

Processor: TM251MESE is equipped with a high-performance processor that can handle complex control tasks and real-time data processing.

Memory: Having sufficient memory to support large-scale program and data storage requirements.

Input/output module:

Digital and Analog I/O: Supports multiple input/output module configurations, including digital and analog input/output, and is compatible with various sensors, actuators, and other devices.

Modular design: Supports modular expansion and can add or replace I/O modules according to application requirements.

Communication interface:

Built in interfaces: equipped with multiple communication interfaces such as Ethernet/IP, Modbus TCP, RS-232/RS-485, etc., supporting integration with other controllers and devices.

Expansion Interface: Supports expansion modules to add more communication options and network connectivity capabilities.

Programming and configuration:

Programming software: Use Schneider Electric's EcoStruxure Control Expert or SoMachine programming software for programming and configuration, supporting multiple programming languages such as Ladder Logic, Structured Text, etc.

Graphic programming: Provides a graphical programming interface to simplify the design and debugging process of control logic.

Features and Applications:

Control and Monitoring: Can be used for various industrial control applications, such as production line automation, process control, equipment monitoring, etc.

Data Collection and Processing: Supports data collection, real-time processing, and data storage, suitable for real-time monitoring and data analysis.

Scalability:

Modular Expansion: Supports adding more I/O points and functions through expansion modules, flexibly meeting different application needs.

Compatibility: Compatible with other Schneider Electric automation equipment, facilitating system integration and upgrades.

Technical specifications (overview):

Processor: High performance processor that supports fast response and processing.

Memory: An appropriate amount of memory used to store programs and data.

Input/Output Module: Supports configuration and expansion of digital and analog I/O modules.

Communication interfaces: including Ethernet/IP, Modbus TCP, RS-232/RS-485, etc.

Programming language: Supports ladder logic, structured text, etc.

Expansion module: Supports modular expansion, adding I/O points and functions.

Application areas:

Manufacturing industry: used for production line control, equipment monitoring, process automation, etc.

Oil and gas: Control oil and gas extraction and processing equipment, monitor operating status.

Chemical industry: Automated control of chemical production processes to ensure process stability.

Water treatment: used for equipment control and process monitoring in water treatment facilities.

System advantages:

High performance: Powerful processing power and memory support for complex control tasks.

Flexibility: Modular design and multiple programming options provide a high degree of flexibility and scalability.

Compatibility: Compatible with other Schneider Electric devices, simplifying system integration.

Easy to program: graphical programming interface and rich programming language support improve programming efficiency.

The Schneider TM251MESE programmable controller is a powerful industrial control device suitable for various automation applications, providing flexible control and monitoring solutions.

Schneider TM251MESE可编程控制器 相关产品:

Lenze MCM09E30-RS0B0 servo motor

KOYO F4-16DA-1 Analog Output Module

| PMB33E-10101-02 | IMMPI01 | EHDB130 |

| PMB33E-00214-01 | IMPCC01 | 1SAP250100R0001 |

| PMB33C-00200-01 | IMRIO02 | 1SAP240100R0001 |

| PMB33C-20216-02 | IMSDO01 | 1SAP240000R0001 |

| PMB31D-20214-03 | IMSET01 | 1SAP140100R0100 |

| PMB31B-10116-01 | INBIM02 | 1SAP180600R0001 |